MENU

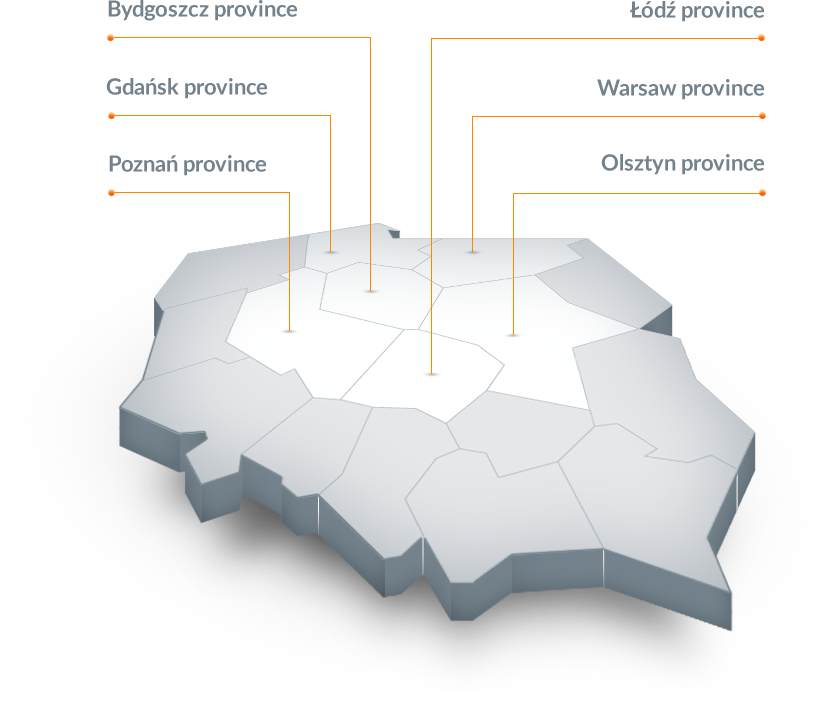

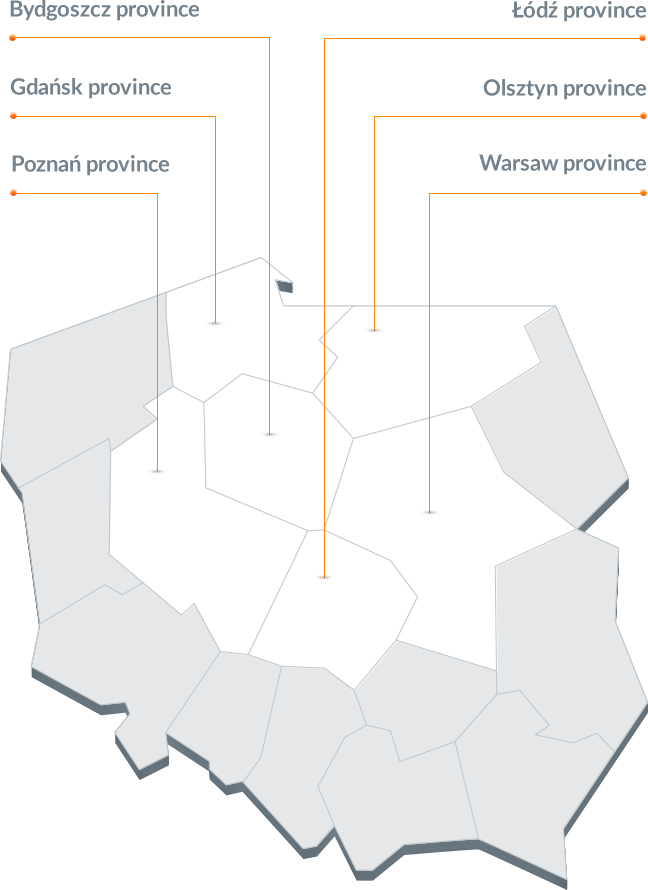

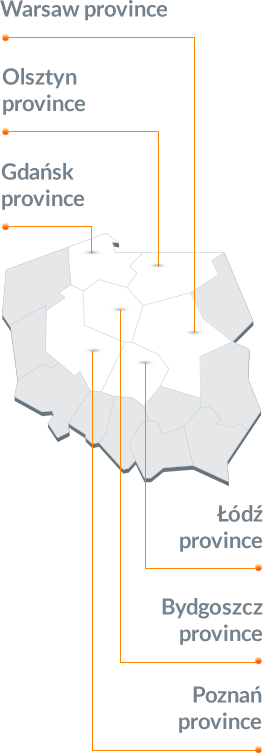

NOVAGO, being one of the leaders in the waste management industry, responsible for the last two stages of the product life cycle (waste collection and management), has an important mission to fulfill. The main goal of NOVAGO is to solve the problem of constantly growing waste volumes and to provide clean energy from renewable sources.

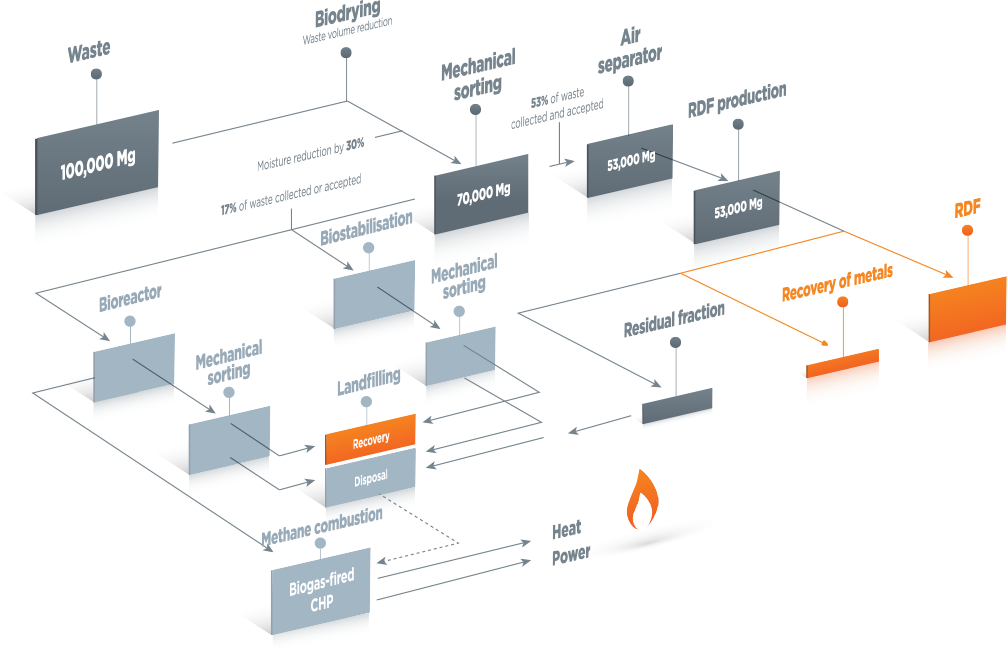

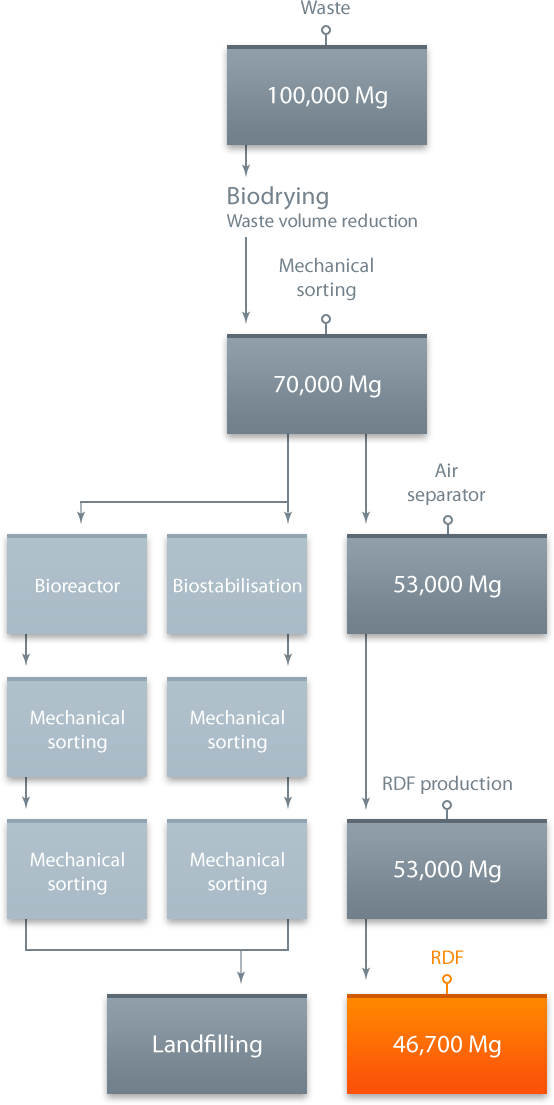

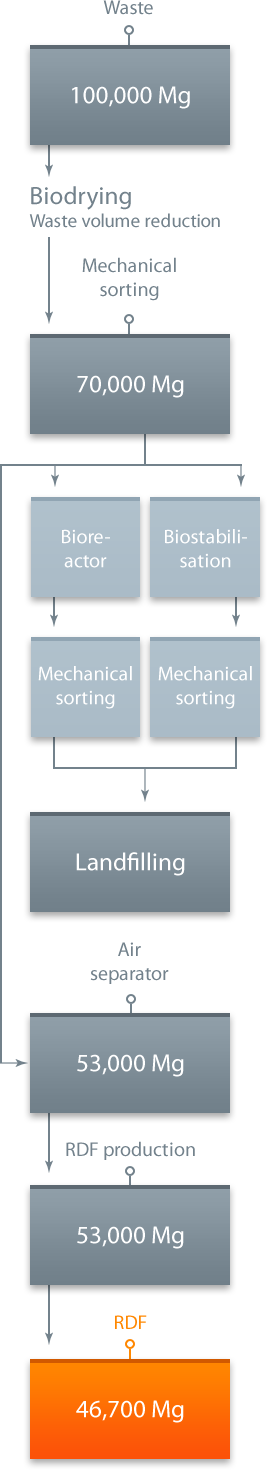

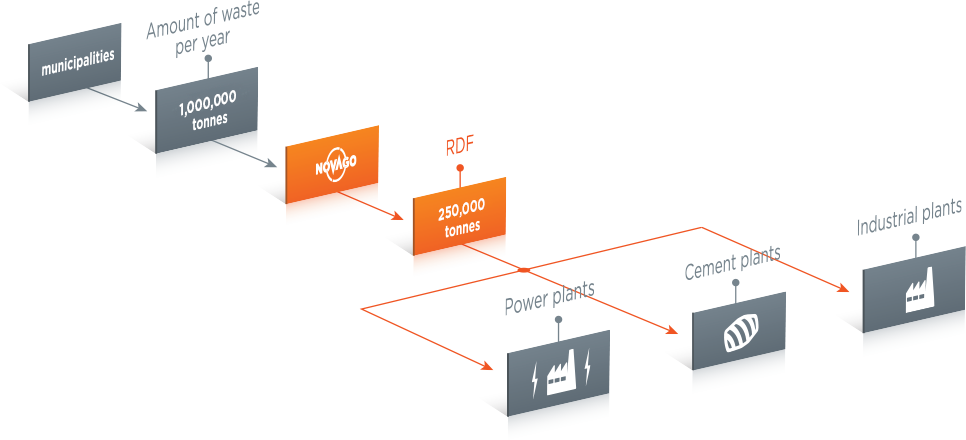

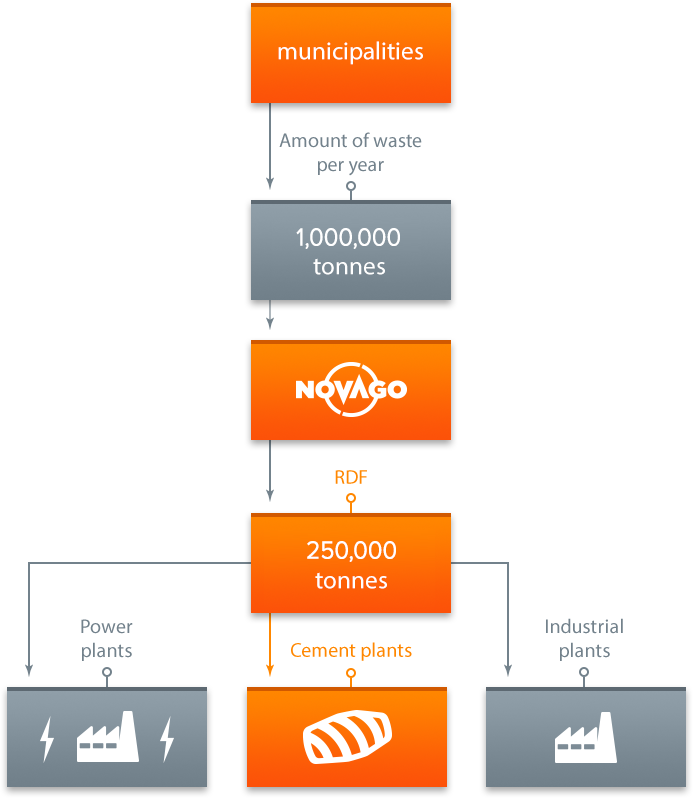

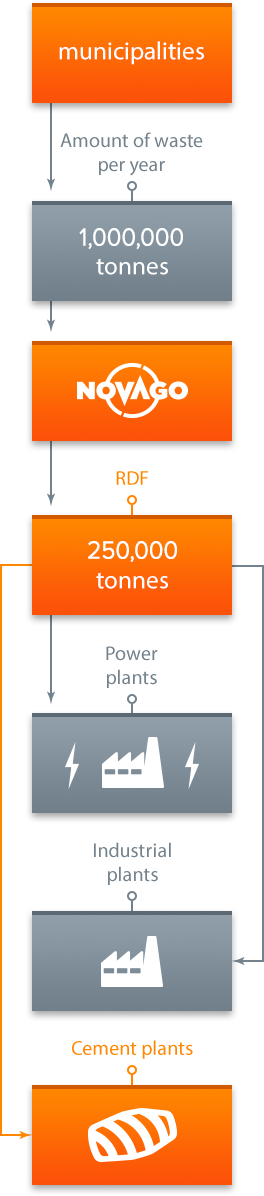

In line with the EU waste hierarchy, NOVAGO seeks to maximize the potential of waste and minimize the amount of waste directed to landfills. After the separation of secondary raw materials, i.e. after the recycling stage, the waste is separated into two fractions: a combustible fraction and an organic fraction. The combustible fraction of waste consists mainly of plastic, foil, paper and wood and is used to produce RDF fuel. The organic fraction of waste is used for the production of biogas, from which electricity and heat are produced in on-site cogeneration installations (cogeneration means the generation of electricity and useful heat at the same time).

We know how to process waste to recover the most valuable thing for society today − clean energy

NOVAGO is engaged in municipal waste treatment, production of RDF, energy generation from renewable sources, waste collection and landfilling of post-processing waste.

NOVAGO’s business comprises:

|  |  |  |  |

| Municipal waste treatment | Production of alternative fuel (RDF) | Waste landfilling | Biogas production | Municipal waste collection |

Our landfill sites have a total area of over 52 ha, but at NOVAGO we prefer to treat waste rather than landfill it.

A major challenge for Poland today is the need to radically reduce the volume of landfilled waste.

Under the EU laws, Poland is required to reduce the volume of biodegradable municipal waste going to landfills to 75%, 50% and 35% of the total amount (by weight) of biodegradable municipal waste produced in 1995, before July 16th 2010, July 16th 2014, and July 16th 2020, respectively.

In accordance with a regulation of the Minister of Economy, from January 1st 2016 certain fraction of waste, which NOVAGO has for years been treating and using to produce alternative fuel, can no longer be landfilled.

NOVAGO plays a key role in the process of Poland’s fulfilling its effective waste management duties imposed by EU directives.

The EU regulates waste management mainly through the following legislative acts:

Directive 2008/98/EC of 19 November 2008 on waste and repealing certain Directives – Framework Directive

The Framework Directive imposed self-sufficiency and proximity principles, under which Member States should take appropriate measures, in cooperation with other Member States where necessary, to establish an integrated and adequate network of installations for the recovery or disposal of mixed municipal waste, using best available methods and techniques ensuring a high level of protection for the environment and public health.

Directive 1999/31/EC of 26 April 1999 on the landfill of waste

Under the Directive, Poland was required to reduce the volume of biodegradable municipal waste going to landfills to 75%, 50% and 35% of the total amount (by weight) of biodegradable municipal waste produced in 1995, before, respectively, July 16th 2010, July 16th 2014, and July 16th 2020.

Directive 2000/76/EC of 4 December 2000 on the incineration of waste

Directive 2004/12/EC of the European Parliament and of the Council amending Directive 94/62/EC on packaging and packaging waste

RDF is an output of high-calorific waste recovery process. RDF is made from combustible components of plastic, paper and wood waste that has been processed and shredded to make it homogenic.

RDF production helps to significantly reduce the volume of landfilled waste. Used as an alternative to coal, RDF contributes to reducing environmental pollution and CO2 emissions. Moreover, when used instead of coal or mazut, RDF shows one more valuable quality − it is practically sulphur free. Plants that use RDF do not emit sulphur to the atmosphere.

See the picture below to find out how this alternative fuel is produced at NOVAGO.