MENU

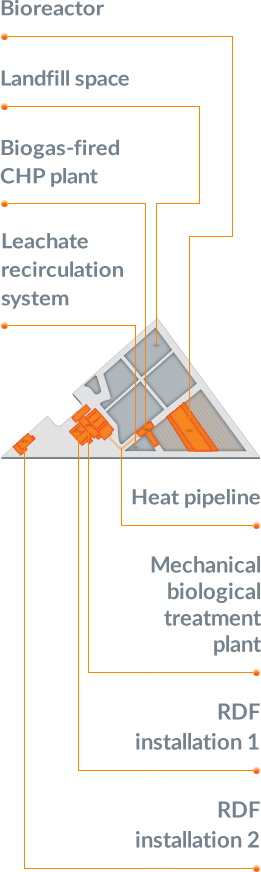

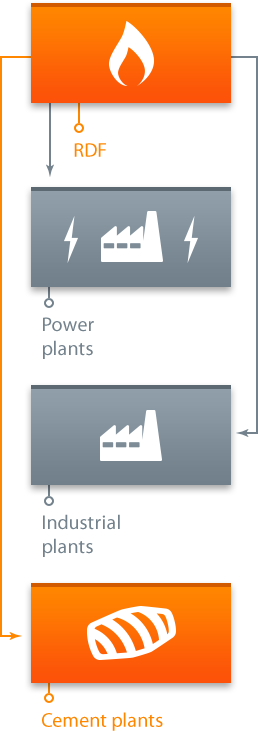

NOVAGO has developed and implemented an innovative method of full-cycle waste processing, in which generated energy is used to produce RDF fuel. In a nutshell, biogas from the organic fraction of waste is used to produce electricity that powers a plant, and heat used to dry RDF fuel. Drying aims to improve the quality parameters of the fuel, especially its calorific value, i.e. the amount of energy that can be obtained by burning it.

NOVAGO uses two fractions of waste with high energy potential.

The first one is organic waste − as a result of the biological and mechanical processes taking place

in organic waste deposits, high-calorific methane is released and then burnt in the biogas-fired CHP plant to produce heat and power.

The other one is combustible waste, such as plastics, paper, wood, etc. It is used to produce RDF, alternative high-calorific fuel which replaces fossil fuels (e.g. coal) in cement kilns.

The installations designed and used by NOVAGO have stood the test of time and now allow us to use

the alternative fuel and at the same time produce heat and power from renewable sources.

What does NOVAGO plant consist of?

More than 12,285,000 tonnes of waste is produced in Poland every year. It could fill up 562 ships the size of Titanic. At NOVAGO, we do everything we can to recover as much as possible.

NOVAGO plants use a waste-to-energy technology that is unique in Poland. NOVAGO uses two fractions of waste with high energy potential, which gives NOVAGO’s RDF top quality and high calorific value.

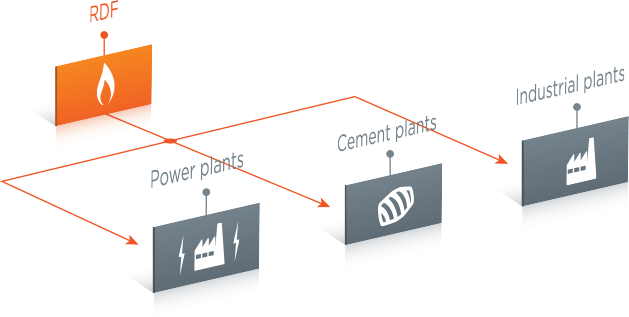

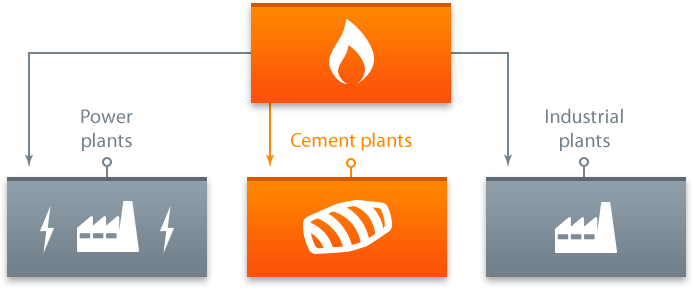

NOVAGO produces alternative high-calorific fuel from waste. Because of its high energy content, the fuel can successfully replace traditional fossil fuels, e.g. coal.

RDF produced by NOVAGO has calorific value comparable to that of coal − 20 MJ/kg. RDF’s another advantage is that it is made from waste which not so long ago used to end up in landfill sites.

RDF is clean and affordable energy from waste. RDF production helps to considerably reduce the volume of landfilled waste, thus also decreasing environmental pollution and CO2 emissions.

Environmental aspects of innovative waste management methods.

More than 12,285,000 tonnes of waste is produced in Poland every year. It could fill up 562 ships the size of Titanic. At NOVAGO, we do everything we can to recover as much as possible.

We use biodegradable fraction to make biogas, which markedly reduces the volume of waste going to landfills, and thanks to this we already meet the EU’s stringent requirements for 2020.

For the same reason, we are able to prevent methane emission, a problem that is present in traditional landfill sites.

RDF contributes to lower use of traditional fossil fuels and helps reduce the most harmful emissions (particulates, sulphur and ash).

Alternative fuels are simply better for the world.

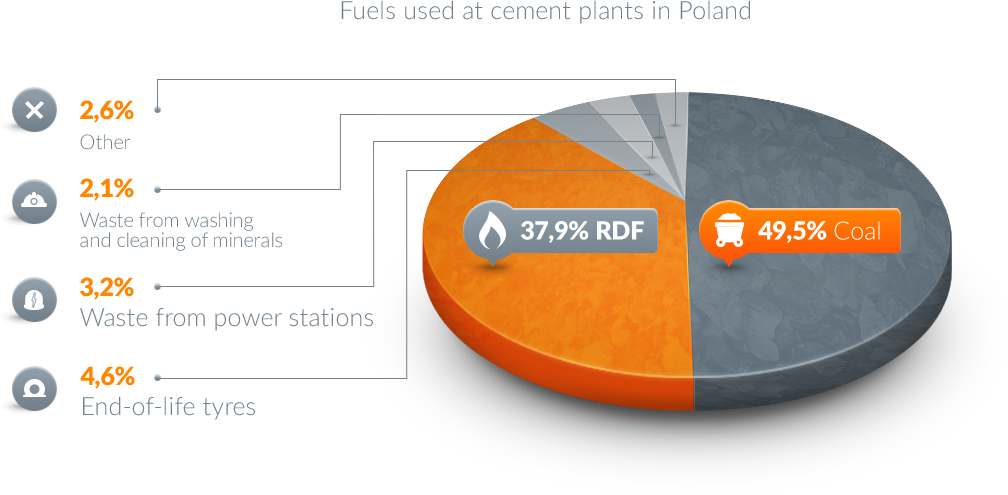

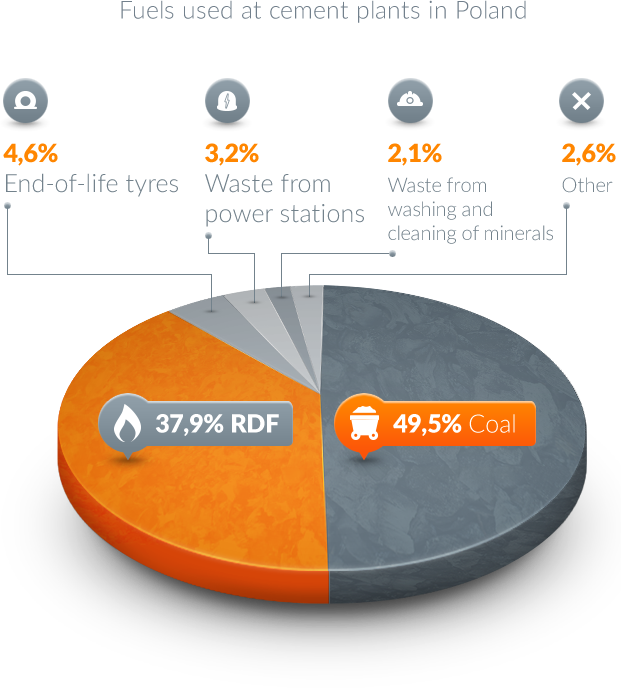

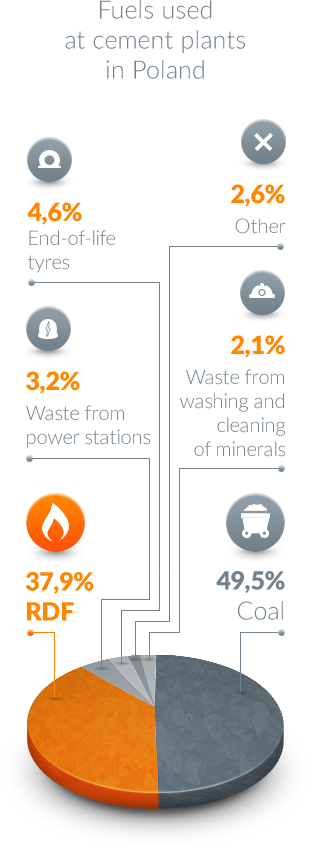

Cement plants are the main customers for our alternative fuel. Their annual RDF requirement may reach even 1,600,000 tonnes. Since cement production is expected to continue to grow steadily in the coming years, their demand for alternative fuel will follow suit.

Every year, the fuel mix used at cement plants changes to the benefit of RDF. There are already cement plants where alternative fuel accounts for as much as 90% of their fuel mix.